|

|

The

initial data for NCM is the program text for a certain machine (G-code)

and the file defining CNC. Besides, part models, components and workpieces

can be loaded from STL files. NCM is designed for working both with

the handmade programs and the programs created with the help of any

CAM system. In the second case one can import all the necessary additional

data (tools, workpiece) from CAM system. The

initial data for NCM is the program text for a certain machine (G-code)

and the file defining CNC. Besides, part models, components and workpieces

can be loaded from STL files. NCM is designed for working both with

the handmade programs and the programs created with the help of any

CAM system. In the second case one can import all the necessary additional

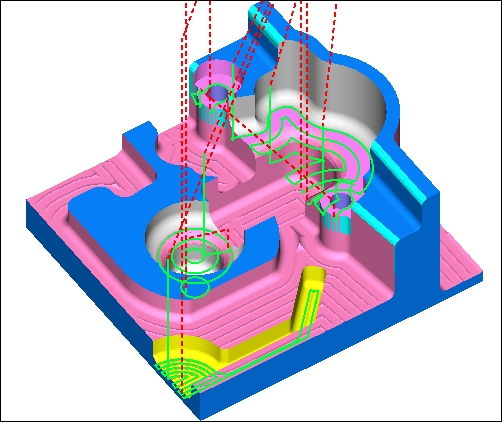

data (tools, workpiece) from CAM system. In

both cases one can either edit or recreate these data from within

NCM. Besides, NCM allows to edit a program text with the immediate

display of the changes made in the graphical window. NCM provides

you with an opportunity to imitate a program execution in various

modes: from a mere trajectory drawing to a realistic imitation of

the removal procedure a workpiece material. in any mode a user has

an access to all current information about coordinates of any point

of a workpiece, a tool, a trajectory as well as all information about

CNC status (feed, speed, mode, etc.). Hence, NCM is a compact product

easy to cope with which can significantly simplify the work with all

the variety of programs for NC machines irrespectively of their origin. In

both cases one can either edit or recreate these data from within

NCM. Besides, NCM allows to edit a program text with the immediate

display of the changes made in the graphical window. NCM provides

you with an opportunity to imitate a program execution in various

modes: from a mere trajectory drawing to a realistic imitation of

the removal procedure a workpiece material. in any mode a user has

an access to all current information about coordinates of any point

of a workpiece, a tool, a trajectory as well as all information about

CNC status (feed, speed, mode, etc.). Hence, NCM is a compact product

easy to cope with which can significantly simplify the work with all

the variety of programs for NC machines irrespectively of their origin.

|

|

|

The

initial data for NCM is the program text for a certain machine (G-code)

and the file defining CNC. Besides, part models, components and workpieces

can be loaded from STL files. NCM is designed for working both with

the handmade programs and the programs created with the help of any

CAM system. In the second case one can import all the necessary additional

data (tools, workpiece) from CAM system.

The

initial data for NCM is the program text for a certain machine (G-code)

and the file defining CNC. Besides, part models, components and workpieces

can be loaded from STL files. NCM is designed for working both with

the handmade programs and the programs created with the help of any

CAM system. In the second case one can import all the necessary additional

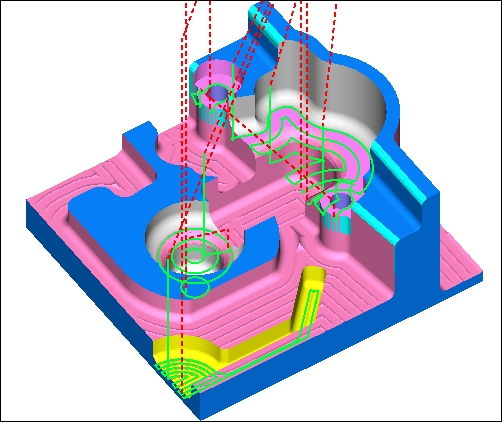

data (tools, workpiece) from CAM system. In

both cases one can either edit or recreate these data from within

NCM. Besides, NCM allows to edit a program text with the immediate

display of the changes made in the graphical window. NCM provides

you with an opportunity to imitate a program execution in various

modes: from a mere trajectory drawing to a realistic imitation of

the removal procedure a workpiece material. in any mode a user has

an access to all current information about coordinates of any point

of a workpiece, a tool, a trajectory as well as all information about

CNC status (feed, speed, mode, etc.). Hence, NCM is a compact product

easy to cope with which can significantly simplify the work with all

the variety of programs for NC machines irrespectively of their origin.

In

both cases one can either edit or recreate these data from within

NCM. Besides, NCM allows to edit a program text with the immediate

display of the changes made in the graphical window. NCM provides

you with an opportunity to imitate a program execution in various

modes: from a mere trajectory drawing to a realistic imitation of

the removal procedure a workpiece material. in any mode a user has

an access to all current information about coordinates of any point

of a workpiece, a tool, a trajectory as well as all information about

CNC status (feed, speed, mode, etc.). Hence, NCM is a compact product

easy to cope with which can significantly simplify the work with all

the variety of programs for NC machines irrespectively of their origin.