|

|

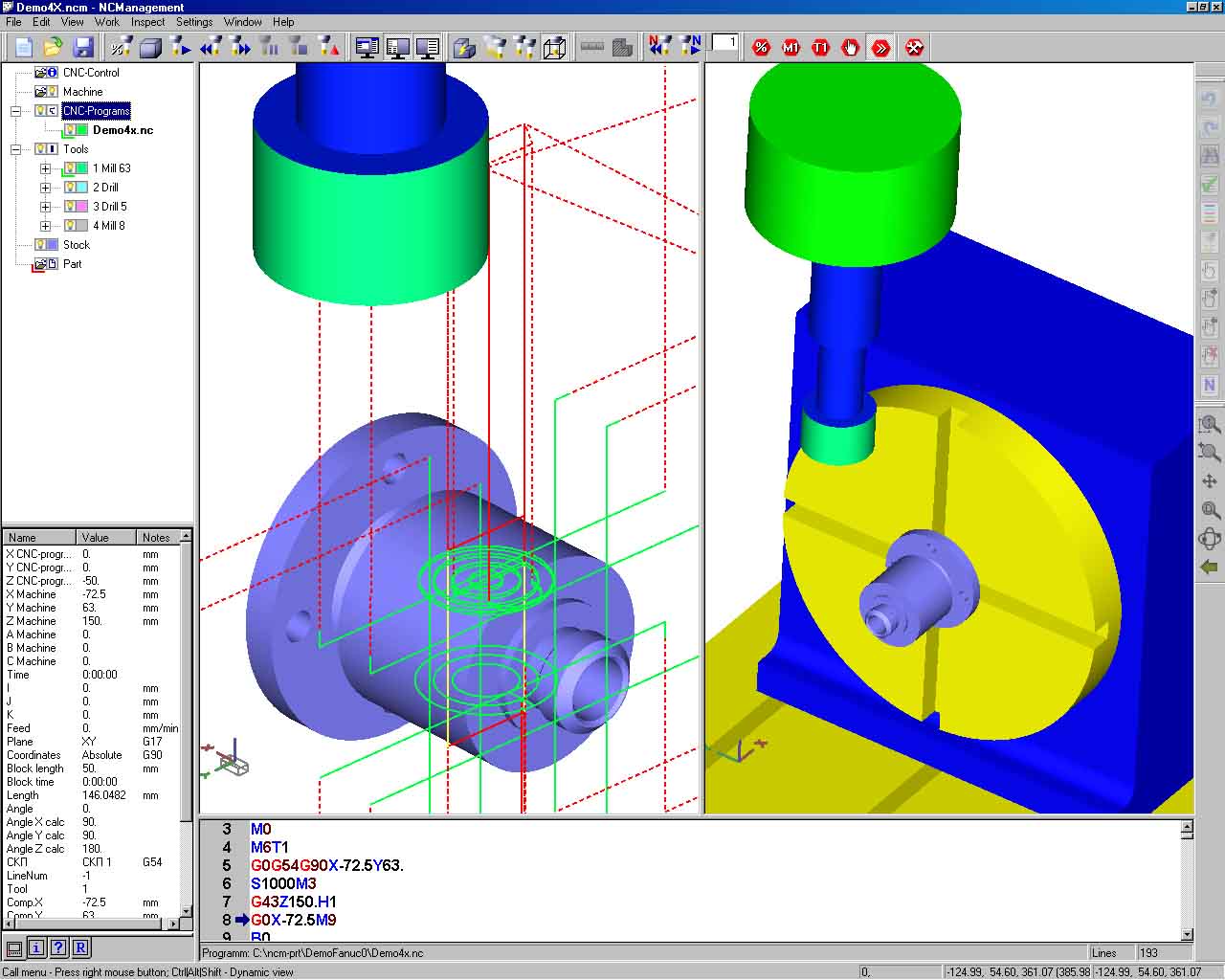

Trajectories reading, interpreting and drawing

Imitation of processing

Tools

Workpiece

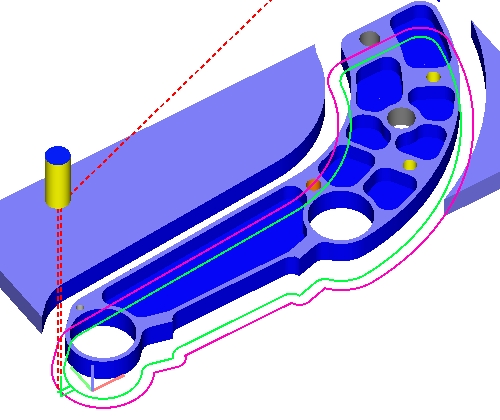

Trajectories reading, interpreting and drawing

NCM reads the file with CNC program (G–code) and interprets it according

to the CNC model established at the moment. This model is loaded from

the file describing CNC. The read trajectories are displayed in the

graphical window as three-dimensional curves. View management allows

to arbitrarily change the viewpoint, select the scale, set standard

views, etc. Feed and fast motion, cycles and subprograms are highlighted

by the line color and type. Display modes in which compensation is/is

not taken into account are possible. Dynamic bindings allow to accurately

measure the co-ordinates of any point on the trajectory as well as

the distance between points. The textbox displays the program text.

Any changes in the text are immediately displayed in the graphical

window. At that you can view the initial and the edited program simultaneously.

There is an opportunity to change the color of separate sections of

the program text depending on the value of this or that parameter

(the type of compensation, the feedrate, the tool used, etc.). This

opportunity is provided in order to simplify the analysis. Top

NCM reads the file with CNC program (G–code) and interprets it according

to the CNC model established at the moment. This model is loaded from

the file describing CNC. The read trajectories are displayed in the

graphical window as three-dimensional curves. View management allows

to arbitrarily change the viewpoint, select the scale, set standard

views, etc. Feed and fast motion, cycles and subprograms are highlighted

by the line color and type. Display modes in which compensation is/is

not taken into account are possible. Dynamic bindings allow to accurately

measure the co-ordinates of any point on the trajectory as well as

the distance between points. The textbox displays the program text.

Any changes in the text are immediately displayed in the graphical

window. At that you can view the initial and the edited program simultaneously.

There is an opportunity to change the color of separate sections of

the program text depending on the value of this or that parameter

(the type of compensation, the feedrate, the tool used, etc.). This

opportunity is provided in order to simplify the analysis. Top

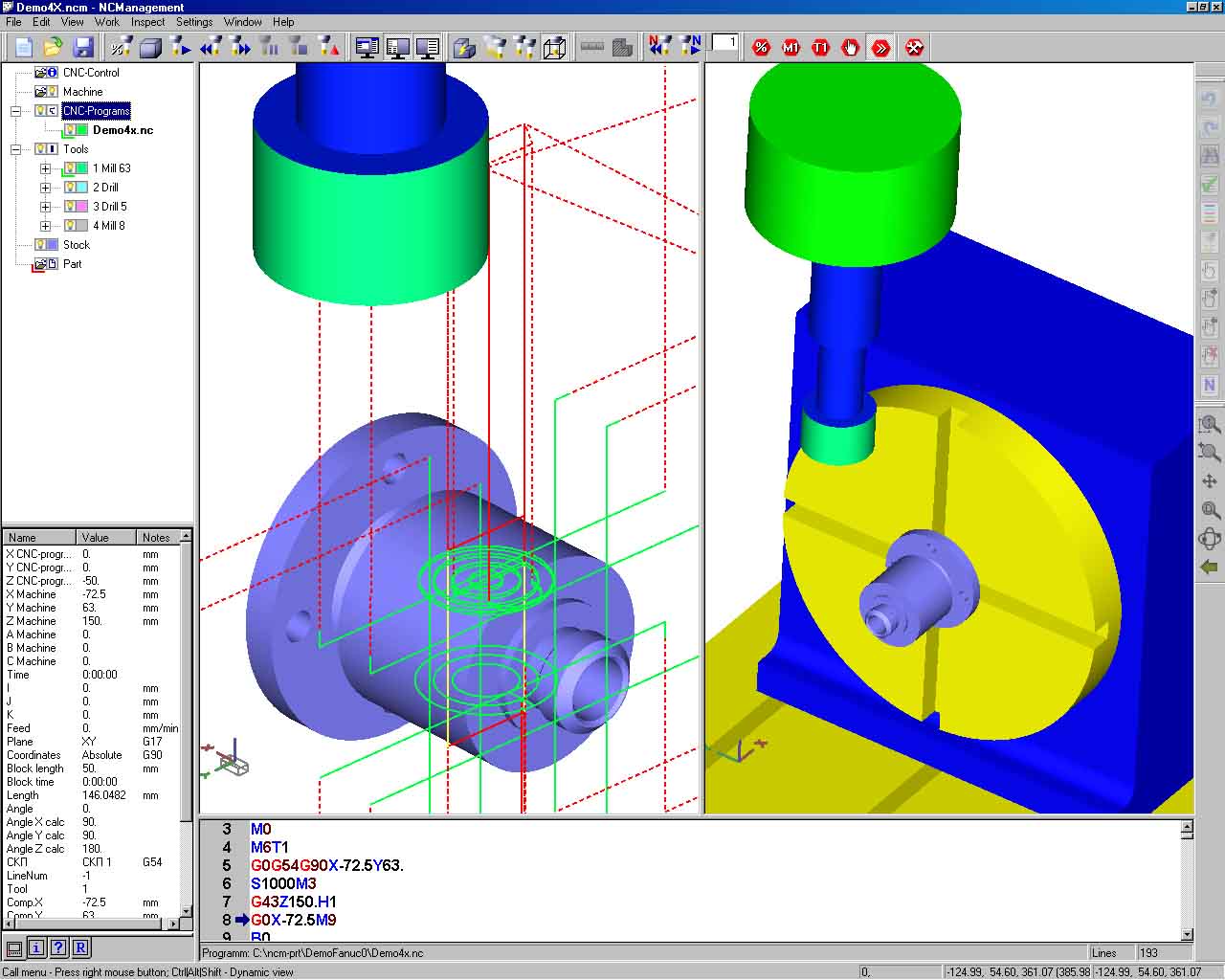

Imitation of processing

While imitating the processing NCM displays the tool movements and

the current values of working parameters (co-ordinates, feedrate,

cooling, etc.), and calculates the time of processing. There is an

opportunity to move arbitrarily within the program either forward

or backward as well as to execute the program automatically either

step by step or from/till the selected block. NCM displays the removal

procedure of workpiece material while processing according to the

set program, i.e. from any point you can see in dynamics the way the

form of a workpiece changes. The sections where the tool collides

with the surface in fast motion are highlighted by color. The co-ordinates

of every point on either processed or unprocessed surface as well

as (for the processed surface only) the number of the initial program

block executing which this point was obtained are displayed at any

stage. There is also an opportunity to plot an arbitrary section of

a workpiece being processed. The user can imitate the work either

of all the loaded programs or of any program taken separately, or

of any other program segment. Top

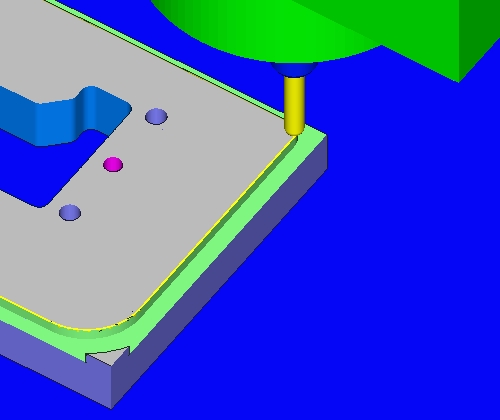

While imitating the processing NCM displays the tool movements and

the current values of working parameters (co-ordinates, feedrate,

cooling, etc.), and calculates the time of processing. There is an

opportunity to move arbitrarily within the program either forward

or backward as well as to execute the program automatically either

step by step or from/till the selected block. NCM displays the removal

procedure of workpiece material while processing according to the

set program, i.e. from any point you can see in dynamics the way the

form of a workpiece changes. The sections where the tool collides

with the surface in fast motion are highlighted by color. The co-ordinates

of every point on either processed or unprocessed surface as well

as (for the processed surface only) the number of the initial program

block executing which this point was obtained are displayed at any

stage. There is also an opportunity to plot an arbitrary section of

a workpiece being processed. The user can imitate the work either

of all the loaded programs or of any program taken separately, or

of any other program segment. Top

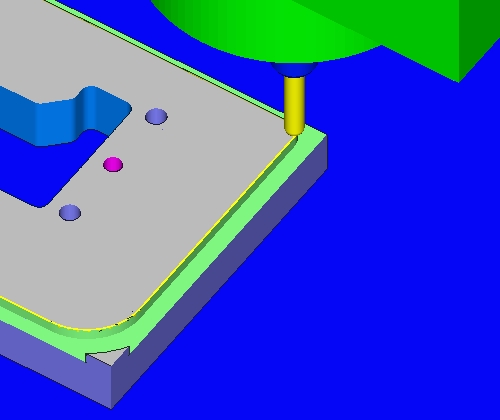

Tools

NCM allows to set tool parameters directly or to import them from the CAM-system.

In the first case you should indicate for every tool its geometrical size and position it must be placed in.

In the course of processing imitation a tool can be displayed as a wire-frame or half-tone image, or as a conventional marker. You can set the tool color and the degree of tool transparency. Top

Workpiece

NCM provides an opportunity to set the workpiece form and size directly

or to import these data from the CAD/CAM system.You can set a

cylindric workpiece or a workpiece in the form of a plate

(rectangular parallelepiped) directly, i.e. “within” NCM.

The workpiece size and position regarding the co-ordinate system of a

machine can be indicated manually or calculated automatically by CNC

programs dimensions taking the offset into account. A

workpiece of an arbitrary form can be imported from any CAD or

CAD/CAM system that contains STL interface.

Top

|

|

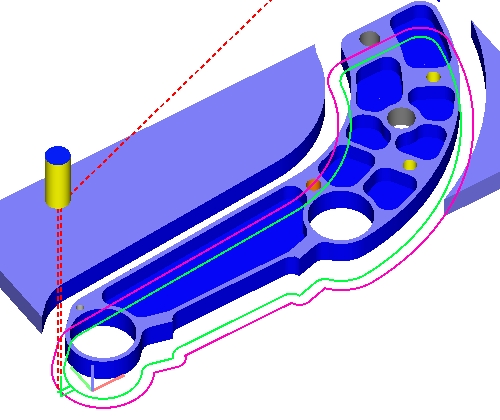

NCM reads the file with CNC program (G–code) and interprets it according

to the CNC model established at the moment. This model is loaded from

the file describing CNC. The read trajectories are displayed in the

graphical window as three-dimensional curves. View management allows

to arbitrarily change the viewpoint, select the scale, set standard

views, etc. Feed and fast motion, cycles and subprograms are highlighted

by the line color and type. Display modes in which compensation is/is

not taken into account are possible. Dynamic bindings allow to accurately

measure the co-ordinates of any point on the trajectory as well as

the distance between points. The textbox displays the program text.

Any changes in the text are immediately displayed in the graphical

window. At that you can view the initial and the edited program simultaneously.

There is an opportunity to change the color of separate sections of

the program text depending on the value of this or that parameter

(the type of compensation, the feedrate, the tool used, etc.). This

opportunity is provided in order to simplify the analysis. Top

NCM reads the file with CNC program (G–code) and interprets it according

to the CNC model established at the moment. This model is loaded from

the file describing CNC. The read trajectories are displayed in the

graphical window as three-dimensional curves. View management allows

to arbitrarily change the viewpoint, select the scale, set standard

views, etc. Feed and fast motion, cycles and subprograms are highlighted

by the line color and type. Display modes in which compensation is/is

not taken into account are possible. Dynamic bindings allow to accurately

measure the co-ordinates of any point on the trajectory as well as

the distance between points. The textbox displays the program text.

Any changes in the text are immediately displayed in the graphical

window. At that you can view the initial and the edited program simultaneously.

There is an opportunity to change the color of separate sections of

the program text depending on the value of this or that parameter

(the type of compensation, the feedrate, the tool used, etc.). This

opportunity is provided in order to simplify the analysis. Top While imitating the processing NCM displays the tool movements and

the current values of working parameters (co-ordinates, feedrate,

cooling, etc.), and calculates the time of processing. There is an

opportunity to move arbitrarily within the program either forward

or backward as well as to execute the program automatically either

step by step or from/till the selected block. NCM displays the removal

procedure of workpiece material while processing according to the

set program, i.e. from any point you can see in dynamics the way the

form of a workpiece changes. The sections where the tool collides

with the surface in fast motion are highlighted by color. The co-ordinates

of every point on either processed or unprocessed surface as well

as (for the processed surface only) the number of the initial program

block executing which this point was obtained are displayed at any

stage. There is also an opportunity to plot an arbitrary section of

a workpiece being processed. The user can imitate the work either

of all the loaded programs or of any program taken separately, or

of any other program segment. Top

While imitating the processing NCM displays the tool movements and

the current values of working parameters (co-ordinates, feedrate,

cooling, etc.), and calculates the time of processing. There is an

opportunity to move arbitrarily within the program either forward

or backward as well as to execute the program automatically either

step by step or from/till the selected block. NCM displays the removal

procedure of workpiece material while processing according to the

set program, i.e. from any point you can see in dynamics the way the

form of a workpiece changes. The sections where the tool collides

with the surface in fast motion are highlighted by color. The co-ordinates

of every point on either processed or unprocessed surface as well

as (for the processed surface only) the number of the initial program

block executing which this point was obtained are displayed at any

stage. There is also an opportunity to plot an arbitrary section of

a workpiece being processed. The user can imitate the work either

of all the loaded programs or of any program taken separately, or

of any other program segment. Top